But everyone knows bias binding is a pain to make perfectly, right? I've been visiting with my friends over at Hayes Sewing Machine Co. again and have some tips to try for perfecting the look of bias binding at home.

Supplies you will need to make bias tape:

-generous piece of fabric, depending on how much tape you are making (sorry, bias cuts take a lot and waste a lot of fabric unless you seam it to death)

-see through ruler ( I like 2" by 18" size)

-bias tape maker

-rotary cutter

- iron

-bias binding foot (see what is available for your machine)

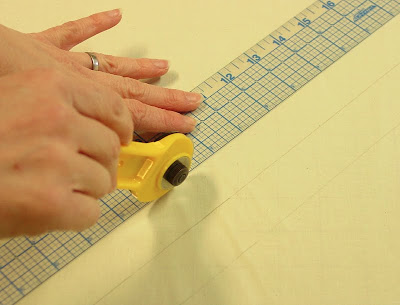

Step one in making bias tape and binding is to cut strips of fabric on the bias and seam them if necessary. Bias just means a 45 degree angle to the grain or selvedge.

You can find the angle by folding up the bottom corner of your piece of fabric to meet the perpendicular edge. It's easy to get exact on a check or stripe. Truthfully, it won't matter much if your off by a few degrees.

The best way to cut even, accurate strips is to use a see-through ruler and a rotary cutter. To get a long piece, you may need to seam your strips. It looks like this:

I've read the directions that came with my 3/4" bias tape maker and it says for regular cotton fabric, I need to cut 1 3/8" strips to wind up with 3/4" tape and 3/8" binding.

This nifty low tech bias tape maker is my new friend. It comes in different widths for your various projects.

You cut the start of your bias into a point and feed your bias strips through (I'm nudging in with a needle through the slot to get it started) and it comes out the other end, evenly folded and ready to iron.

Feed an inch or two of your strip through the little contraption at a time and hit it with the iron as it comes out the other end. It is so superior to trying to hand fold the strips yourself that I can't even stress enough how essential it is to get one of these! There is also a pricier high tech bias tape maker that does the ironing part for you too, which looks intriguing if you will be making a lot of tape.

If you want to make a boatload of tape, for binding the edge of a quilt, for instance, here is a formula with directions for making and seaming many yards of bias.

Now I've got this lovely, perfectly even piece of bias tape and I want to apply it to the armhole of my trial sundress. I fold it in half again and iron it. I apologize for the boring fabric, but I am trying this out for the first time and don't want to risk the good stuff.

At the sewing store, I watched a demo of applying bias binding with a special bias binder foot and succumbed to buying one for my Babylock. It's supposed keep your binding folded and aligned, top and bottom by way of a plastic guide not unlike the bias tape maker. You feed it through the guide and line up your needle position where you want it, so both sides of the binding are caught in the stitching. It looked so easy when Pam Hayes did it. Hmmm, we'll see....

It's not so easy to get the first bit started so I thought of a workaround. I attached some threads to the beginning to have something to help pull it through before the feed dogs can grab it and take over.

This is going swimmingly!

The part where you sandwich the body fabric of the dress into the binding is a little harder. There is a slotin the foot to tuck the body fabric into but it can still shift and come out. You just have to be vigilant and keep a needle handy for poking it back into place. Starting over midway is not an option. Mess up, and you have to rip it all out and start over.

I'm happy with the result, though. It really does look professional!

I used to be a clothing designer in New York City, then I chucked it all to start a family. I stay busy as an independent designer of kids’ clothing and textiles for various companies, and for my own label “chirp & bloom”. This is my personal blog, where I keep my notes on all things vintage, green, handmade, indie, kid-friendly, and whatever else inspires me to keep evolving. Just for fun, I feature artisans I discover at indie craft shows and share sewing and other DIY projects through tutorials. Thanks for visiting!

I used to be a clothing designer in New York City, then I chucked it all to start a family. I stay busy as an independent designer of kids’ clothing and textiles for various companies, and for my own label “chirp & bloom”. This is my personal blog, where I keep my notes on all things vintage, green, handmade, indie, kid-friendly, and whatever else inspires me to keep evolving. Just for fun, I feature artisans I discover at indie craft shows and share sewing and other DIY projects through tutorials. Thanks for visiting!

All personal designs, images, and written words in this blog are copyrighted by Rebecca Harkin unless otherwise credited. Feel free to link back to my posts all you want, but please do not copy my photos or words without my permission.

All personal designs, images, and written words in this blog are copyrighted by Rebecca Harkin unless otherwise credited. Feel free to link back to my posts all you want, but please do not copy my photos or words without my permission.

1 comment:

I just bought a bias tape maker- and haven't done anything with it yet. But now I am inspired! I have just discovered Japanese patterns myself- I looove the pictures alone. I have my first project cut out- I am excited to get started on it.

I love your blog, by the way!

Post a Comment